Product Description

Features

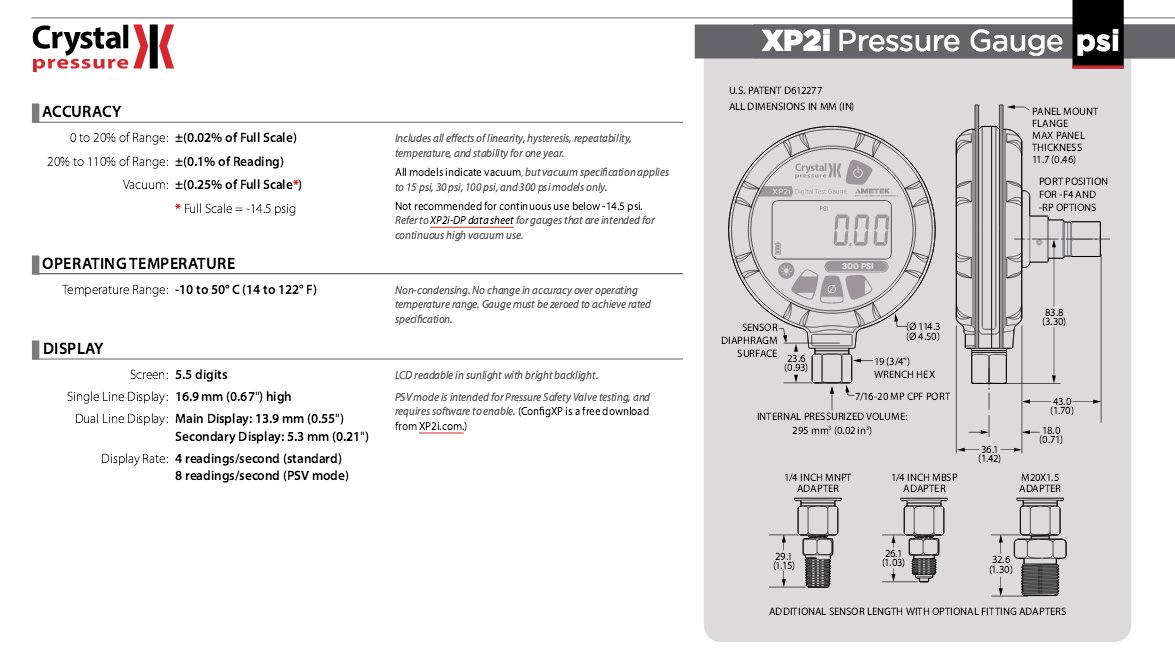

- Manufactured by Crystal Engineering

- Specified in percent of reading like deadweight testers

- Easy to read display - day or night

- 5 full digits - great for leak testing

- Available in ranges from 15 PSI to 15,000 PSI

- Pressure units easily accessible

- Capture peak High or Low pressure for relief valve testing

- Water resistant case (per NEMA4 and IP66)

The Crystal XP2i Series are unlike any other pressure gauges. Their looks, performance, and construction are different from anything else available.

Pressure gauges from the XP2i Series are very rugged. Their displays are protected by a hard polycarbonate lens, and their circuitry is mounted in elastomer for shock resistance. The case and sensor are made of stainless steel to provide resistance to corrosion as well as an excellent barrier to emissions from cell phones, two-way radios, and other electrically noisy equipment. The case is gasketed and water resistant per NEMA4 and IP66. A replaceable filter in the sensor keeps out debris.

Unlike mechanical gauges, Crystal XP2i Series pressure gauges have the ability to survive large over-pressure events with no change in calibration.

The XP2i Series is very easy to use. No menus - just buttons. They can be calibrated via the keypad or the RS232 port. The display backlight is one of the best available on this type of pressure gauge. Combine an XP2i with a pressure controller, and you can calibrate XP2i's automatically.

The Crystal XP2i Series is very accurate. The XP2i is rated in percent of reading - like deadweight testers - but unlike deadweight testers, they're not affected by ambient temperature or local gravity. These pressure gauges are full temperature compensated, so the accuracy is the same over the entire operating temperature range. They can even be used to measure vacuum. Because the rating is "of reading", one XP2i can often replace two or more ordinary gauges.